Liphaephe tse Welded

Tlhaloso ea Lihlahisoa

Liphaephe tse tjheseditsweng, tse tsejoang hape e le liphaephe tsa tšepe tse tjheseditsweng, li etsoa ka ho phutholla lipoleiti tsa tšepe kapa liropo ho etsa sebopeho sa tšubu ebe li tjheseletsa manonyeletso. Hammoho le liphaephe tse se nang moedi, ke e 'ngoe ea lihlopha tse peli tse ka sehloohong tsa liphaephe tsa tšepe. Likarolo tsa tsona tsa mantlha ke tlhahiso e bonolo, litšenyehelo tse tlase, le mefuta e mengata ea litlhaloso.

I. Tlhophiso ea Motheo: Tlhophiso ka Ts'ebetso ea ho Welding

Mekhoa e fapaneng ea ho tjheseletsa e khetholla ts'ebetso ea liphaephe tse tjheselitsoeng. Ho na le mefuta e meraro e meholo:

• Phaephe e Welded ea Longitudinal (ERW): Kamora ho phutholla moqomo oa tšepe karolong e chitja kapa e sekoere, moalo o tjheselletsoa ka bolelele (ka bolelele) ho pholletsa le phaephe. Sena se fana ka katleho e phahameng ea tlhahiso le litšenyehelo tse tlase, e leng se etsang hore e lokele ho tsamaisoa ha mokelikeli o nang le khatello e tlase (joalo ka metsi le khase) le lits'ebetso tsa tšehetso ea sebopeho. Litlhaloso tse tloaelehileng li kenyelletsa bophara bo bonyenyane le bo mahareng (hangata ≤630mm).

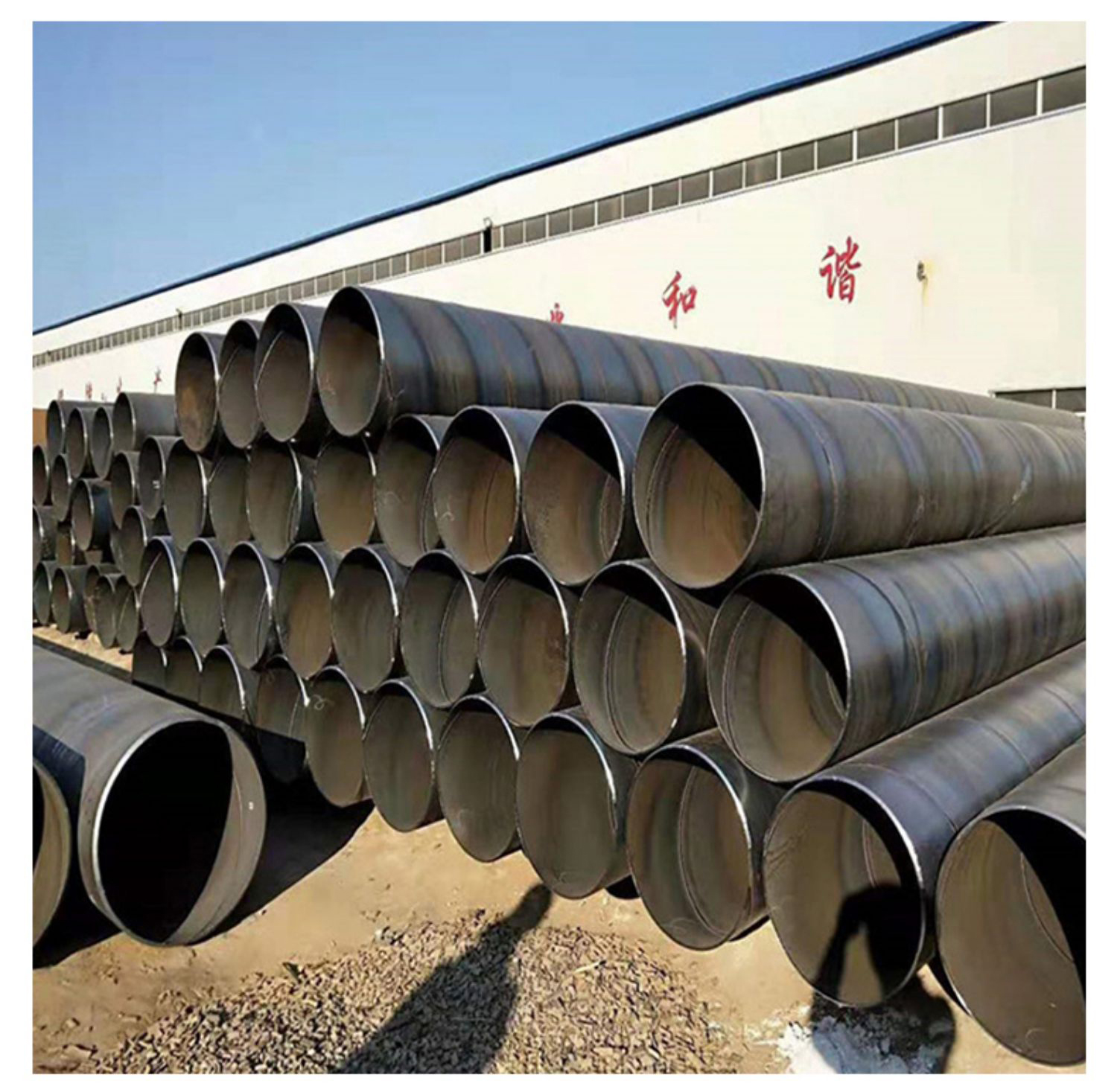

• Pipe e Welded e Potolohileng (SSAW): Moqomo wa tshepe o phuthoa ka lehlakoreng le kang helical mme moqomo o phuthelwa ka nako e le nngwe, e leng se etsang hore ho be le weld e spiral. Moqomo wa weld o hatellwa ka ho lekana, o fana ka kganyetso e phahameng ya ho kgwehla le ho kobeha ha o bapiswa le pipe e otlolohileng e welded. Sena se dumella tlhahiso ya diphaephe tse bophara bo boholo (ho fihlela ho 3,000mm ka bophara) mme haholo-holo e sebediswa bakeng sa ho tsamaisa metsi a kgatello e phahameng (jwalo ka diphaephe tsa oli le kgase ya tlhaho) le diphaephe tsa drainage tsa masepala.

• Phaephe e tjheseditsweng ka tshepe e sa ruseng: E entswe ka lakane/strip ya tshepe e sa ruseng, e tjheseditswe ka ditshebetso tse kang TIG (tungsten inert gas arc welding) le MIG (metal metal arc welding). E na le ts'enyeho le kganyetso ya mocheso o phahameng wa tshepe e sa ruseng mme e loketse ditshebetso tse hlokang thepa ya boleng bo hodimo, jwalo ka ho sebetsana le dijo, dikhemikhale le disebediswa tsa bongaka. E sebediswa hangata diphaepheng tse nyane le tse mahareng tse nepahetseng.

II. Melemo e Meholo

1. Litšenyehelo tse Tlase le Tlhahiso e Phahameng: Ha e bapisoa le phaephe e se nang moqhaka (e hlokang lits'ebetso tse rarahaneng tse kang ho phunya le ho phutholla), phaephe e tjhitilweng e fana ka ts'ebeliso e phahameng ea thepa e tala le ts'ebetso e khuts'oane ea tlhahiso. Litšenyehelo hangata li tlase ka 20%-50% bakeng sa litlhaloso tse tšoanang. Ho feta moo, e ka hlahisoa ka lihlopha le ka ho tsoelang pele ho fihlela tlhoko e kholo.

2. Litlhaloso tse Tenyetsehang: Liphaephe tse nang le bophara bo fapaneng (ho tloha ho limilimithara tse 'maloa ho isa ho limithara tse' maloa), botenya ba lebota, le likarolo tse tšekaletseng (tse chitja, tse sekoere, le tse khutlonnetsepa) li ka hlahisoa ha ho hlokahala ho fihlela litlhoko tsa botho tsa lits'ebetso tse fapaneng, ho kenyeletsoa kaho le indasteri.

3. Ho Sebetsa Habonolo: Thepa e tšoanang le li-weld tse tsitsitseng li nolofalletsa ho seha, ho cheka, ho kobeha le ts'ebetso e 'ngoe ea ts'ebetso e latelang, ho netefatsa ho kenngoa ho bonolo.

III. Libaka tse ka Sehloohong tsa Kopo

• Indasteri ea Kaho: E sebelisoa liphaepheng tsa phepelo ea metsi le tsa drainage, liphaepheng tsa tšireletso ea mollo, litšehetso tsa sebopeho sa tšepe (joalo ka li-scaffolding le li-studs tsa lebota la likharetene), liforeimi tsa mamati le lifensetere (liphaephe tse thibiloeng ka khutlonnetsepa), jj.

• Lekala la Liindasteri: Li sebelisoa e le liphaephe tsa ho tsamaisa metsi tse nang le khatello e tlase (metsi, moea o hatelletsoeng, mouoane), liphaephe tse tšehetsang lisebelisoa, li-guardrail tsa workshop, jj.; liphaephe tse tšetsoeng ka spiral tse bophara bo boholo li sebelisoa liphaepheng tsa oli le khase ea tlhaho tse tsamaeang hole.

• Lekala la Masepala: E sebediswa diphaepheng tsa metsi a ditoropong, marangrang a diphaephe tsa kgase (kgatello e mahareng le e tlase), dipalo tsa mabone a seterata, ditereilara tsa sephethephethe, jj.

• Bophelo ba Letsatsi le Letsatsi: Liphaephe tse nyane tse tjheseditsweng (tse kang liphaephe tsa tšepe e sa ruseng) li sebelisoa ka har'a li-bracket tsa thepa ea ka tlung le liphaepheng tsa kichine (tse kang liphaephe tsa mosi oa hood ea range hood).

Pontšo ea Sehlahisoa