Lahleloa tšepe valave ea tšepe e sa hloekang

Tlhaloso ea Sehlahisoa

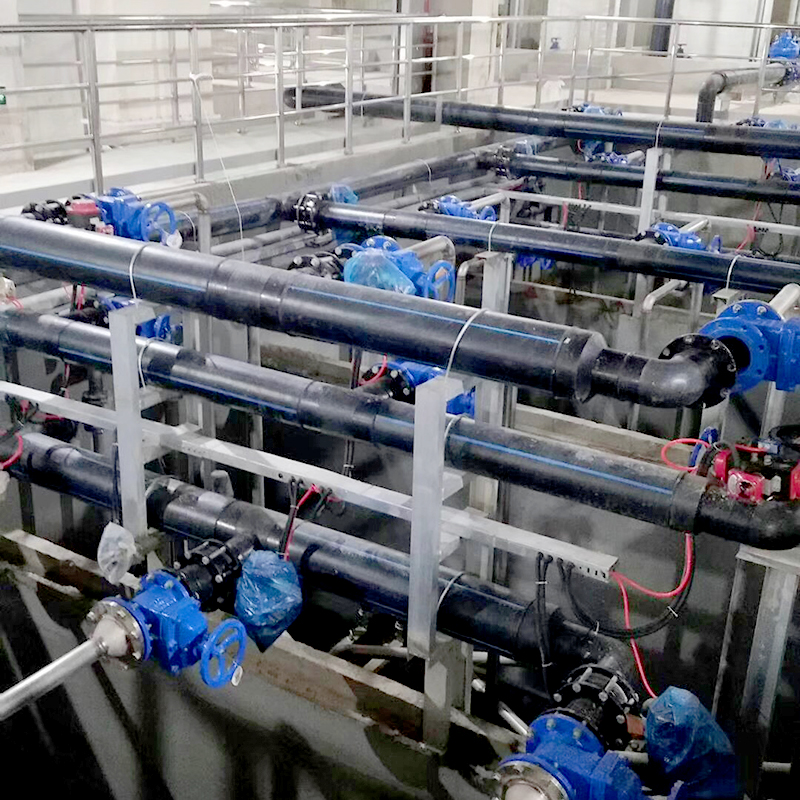

1.Valve e sebelisetsoa ho bula le ho koala phaephe, ho laola tsela eo phallo e tsamaeang ka eona, ho lokisa le ho laola liparamente tsa phetisetso (mocheso, khatello le phallo) tsa lisebelisoa tsa phaephe. Ho ea ka mosebetsi oa eona, e ka aroloa ka valve e koalang, valve ea ho hlahloba, valve e laolang jj.

2.Valve ke karolo ea taolo ea sistimi ea ho tsamaisa mokelikeli, e nang le ho khaola, ho laola, ho faposa, ho thibela ho phatloha ha motlakase, ho laola khatello, ho fokotsa khatello kapa ho fokotsa khatello. Livalve tse sebelisoang litsamaisong tsa taolo ea mokelikeli li tloha ho livalve tse bonolo ka ho fetisisa tsa lefats'e ho ea ho litsamaiso tse rarahaneng ka ho fetisisa tsa taolo ea othomathiki tse sebelisoang mefuteng e fapaneng ea mefuta le litlhaloso.

Tšebeliso ea sehlahisoa

1.Valve ea ho tima: Mofuta ona oa valve o bulehile ebile o koetsoe. Ha e eme holim'a monyako le kantle ho mehloli e batang le ea mocheso, monyako le kantle ho lisebelisoa, mela ea makala a liphaephe (ho kenyeletsoa le riser), e ka boela ea sebelisoa e le valve ea ho ntša metsi le moea. Li-valve tse tloaelehileng tsa ho tima li kenyelletsa valve ea heke, valve ea globe, valve ea bolo le valve ea serurubele.

2.Valve ea ho hlahloba: Mofuta ona oa valve o sebelisetsoa ho thibela phallo e khutlelang morao ea seaplane, tšebeliso ea matla a kinetic a mokelikeli ho bula, phallo e khutlelang morao e koaloa ka bohona. Ho ema sebakeng sa ho ntša pompo, sehokelo sa ho tšoasa le libakeng tse ling ha ho lumelle phallo e khutlelang morao ea mokelikeli.

3.Valve e laolang: valve e laolang e ka fetola spool stroke ho latela tataiso le boholo ba lets'oao, ho fetola palo ea khanyetso ea valve, e le ho fihlela sepheo sa ho laola phallo ea valve. Valve e laolang e qhaqha valve e laolang le valve e laolang e iketsang, 'me valve e laolang ea letsoho kapa e iketsang e arotsoe ka mefuta e mengata, ts'ebetso ea eona e laolang le eona e fapane.

Boemo ba Khoebo

Shandong Zhongao Steel Co. LTD. ke kgwebo e kgolo ya tshepe le tshepe e kopanyang ho sintering, ho etsa tshepe, ho etsa tshepe, ho pitikisa, ho pickling, ho kwahela le ho plating, ho etsa diphaephe, tlhahiso ya motlakase, tlhahiso ya oksijene, samente le kou.

Lihlahisoa tse ka sehloohong li kenyelletsa lakane (khoele e phuthoang e chesang, khoele e batang e entsoeng ka ho bata, boto e bulehileng le e telele e sehiloeng, boto ea pickling, lakane ea galvanized), tšepe ea karolo, bare, terata, phaephe e phuthetsoeng, jj. Lihlahisoa tse ling li kenyelletsa samente, phofo ea slag ea tšepe, phofo ea slag ea metsi, jj.

Har'a tsona, poleiti e ntle e ne e etsa karolo e fetang 70% ea tlhahiso eohle ea tšepe.