Lipoleiti le li-tubes tsa koporo tsa indasteri ea koporo

Ho paka le ho tsamaisa

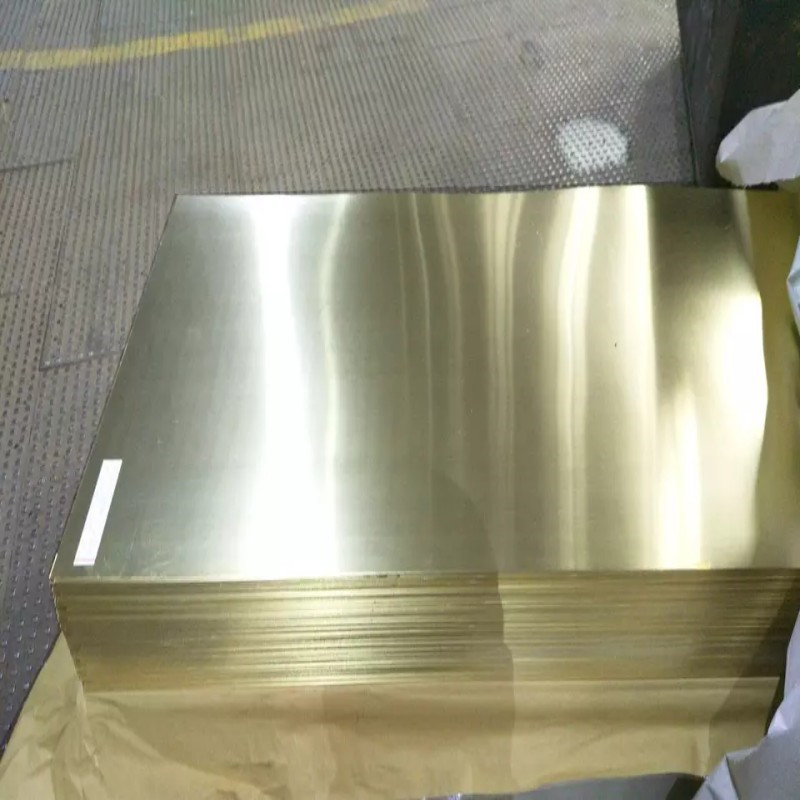

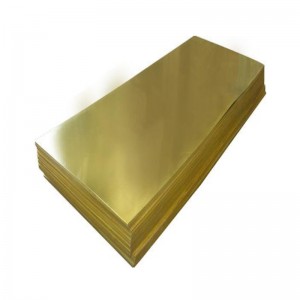

Packaging: Letlapa la koporo la boleng bo holimo la C2680 le hatisitsoeng ho latela maemo ohle

Sephutheloana se tloaelehileng sa ho romela thepa ka ntle ho naha, kapa kamoo ho hlokahalang.

Lehong lebokose lehong phalete lohiloeng mokotla, 3 lintlha ngata

Boema-kepe: Boema-kepe bohle ba China

Ho khetha melemo

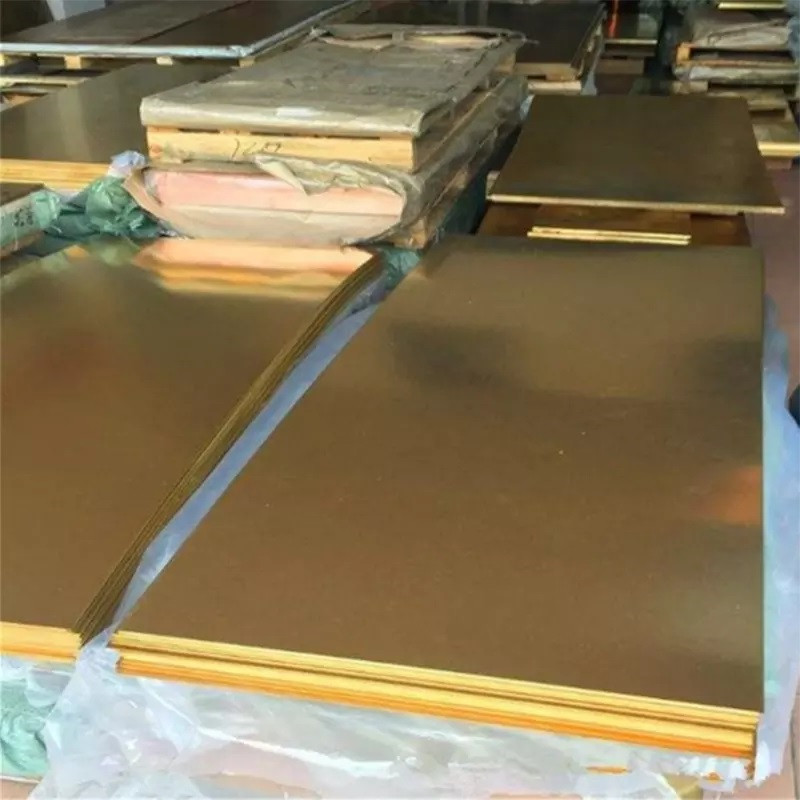

Brass plate e na le khanyetso e phahameng ea kutu. hape e na le polasetiki e ntle. moeeng ho bonolo ho bata le ho chesa ho hatella ho sebetsa. tjheseletsa e bonolo. forging le tin plating. ha ho khatello ea maikutlo corrosion cracking.

1.Lintho tse ncha tsa boleng bo holimo tse sebelisang koporo e ncha e ntle ka ho fetisisa ho netefatsa boleng. Hana ho sebelisa lisebelisuoa tse nchafalitsoeng ho iketsa eka li ncha.

2.Nepahetse. boreledi. hloekisa thepa dimension rona ho nepahala bokaholimo boreleli a bataletseng ntlha makhethe. ha ho burr.

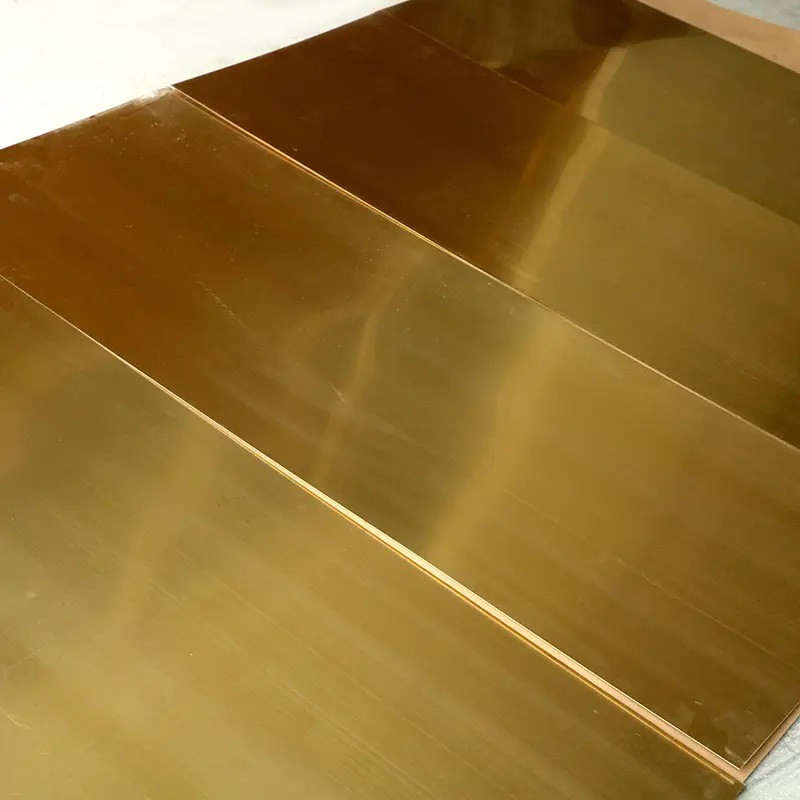

3.Re ka Customize bophara. botenya. bolelele. Re boetse re na le stock ea boleng ka boholo bo tloaelehileng.

4.Ho ba le feme ea bona e lekaneng ho netefatsa letsatsi la ho fana ka litheko tse tlase.

Matla a khampani

Re fana ka lihlahisoa tsa alloy tsa koporo le koporo ka maemo le libopeho tse fapaneng.

Ha re moetsi feela, empa hape re khona ho iketsetsa, ho ntshetsa pele le ho hlahisa lihlahisoa tse fetang 1,000 tsa koporo.

Re motlotlo ho sebeletsa li-alloys tsa hau tsa koporo le tsa koporo ka basebetsi ba rona ba nang le tsebo.

Khamphani e nka ts'ireletso ea tikoloho e le boikarabello ba eona ba mantlha sechabeng, 'me e tsetetse kakaretso ea li-yuan tse limilione tse likete tse 5.56 taolong e felletseng ea tikoloho, paballo ea matla le phokotso ea mesi, le moruo oa selikalikoe.

Ho ntšoa ha mosi le lerōle ka thane e le 'ngoe ea tšepe, ho ntšoa ha sulphur dioxide ka thane e le 'ngoe ea tšepe le litšila tse ling ho fihlile boemong ba pele ba tlhahiso e hloekileng indastering ea tšepe.

Tlhaloso e qaqileng